Aerospace Composites Market was valued US$ 22 Bn in 2017 and is estimated to reach above US$ 40 Bn by 2026 at a CAGR of about 7.5 % during a forecast period of 2018-2026.Phenomenal properties offered by composites such as lightweight materials, high order backlog of aircraft deliveries, high penetration in aircraft structures, improving their lift-to-weight ratio, excellent strength, good stiffness-to-density ratios, stability at high temperature, longer durability and superior physical properties makes them ideal materials for the aerospace hence driving the market. Aerospace composites market is mainly driven by commercial aircraft s coupled with military and defense activities.

Based on resin type aerospace composite market is segmented into thermosetting, epoxy, phenolics, polyester and polyimides. Thermosetting resins is dominating aerospace composites market constitutes more than half market. Thermosetting is followed by epoxy. Epoxy and phenolics in aircraft internal structures provides various benefits such as resistance to corrosives and solvents, fatigue strength, excellent adhesion, resistance to high temperature and heat, and excellent finishing.

Superior impact of thermoset resins such as improved mechanical strength, high corrosion-resistance, and low-weight, over other resin types, have contributed to its increasing liability across varied aerospace utilities. Fiber aerospace composite market is segmented into carbon, ceramic, aramid and glass. Carbon segment is leading the aerospace composites market. Due to its properties such as superior heat-resistance, fire-resistance, high stiffness, and exceptional load carrying properties increasing demand from the military and commercial aerospace segment. In terms of aircraft type aerospace composites market is divided into commercial aircraft, business and general aviation aircraft, military aircraft, civil helicopter, and others (spacecraft).

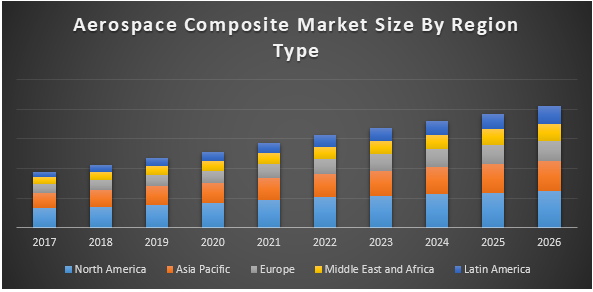

Commercial aircraft is leading market, contributes almost half of market. Military aircraft is a second largest segment. Regionally aerospace composite market is segmented into North America, Europe, Asia Pacific, Middle East & Africa and Latin America. North America holds major share of market. Increasing use of aerospace composites in the commercial and military aircraft is the key reason driving the growth of the North America market. Presence of major aerospace manufacturers and mass production of aerospace parts using aerospace composites are driving the growth of the North America market. North America will mark a higher CAGR in a forecast.

Owing to development led by countries like China, India and Japan Asia Pacific will show a remarkable growth to market. High speed trains, developing domestic aviation and other modes of travelling in Europe will gain market. The Middle East & Africa is also anticipated to have a growth owing to growing number of maintenance, repair, and operational activities in the region.

This information is given by market research company (maximize market research)